Find and fix battery problems faster.

Catch and correct battery issues with data you already collect, from R&D to giga-scale production. Scale quickly, ensure reliability, and get products to market faster.

.png)

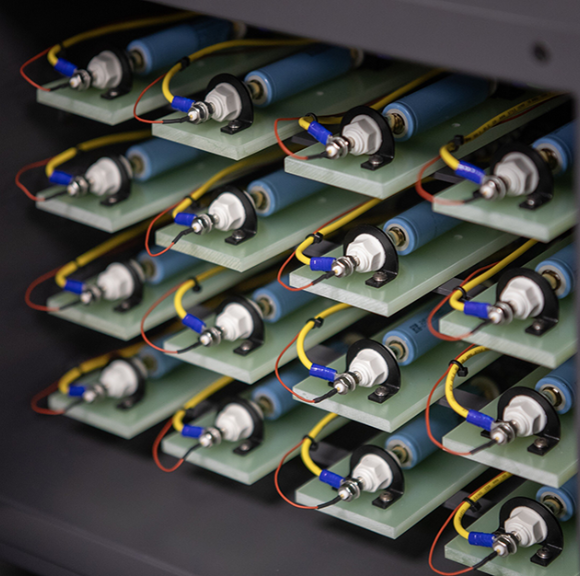

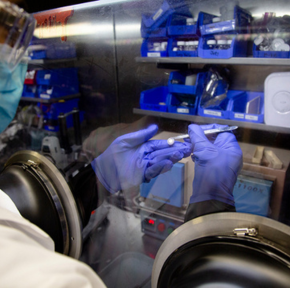

Trusted by leading battery companies and OEMs.

It takes a long time to see if a battery is good or bad, costing OEMs and battery companies billions.

Delayed product launches.

Delaying a product launch can cost significant revenue and competitors can beat you to market.

Slow yield

ramp.

Slow end-of-line quality assurance results in scrap rates of 80% or more, skyrocketing overhead costs, and rapid cash burn.

Shipping defective product.

Defective products result in contract cancellations, returns, recalls, or worse – you're liable for in-field fire hazards.

Catch and correct issues quickly, ensure reliability and get to market faster.

Catch battery issues and quickly understand what caused them across thousands of upstream processes and materials. Plot real-time data in seconds and share reports in a couple of clicks to resolve the problem fast and keep moving forward.

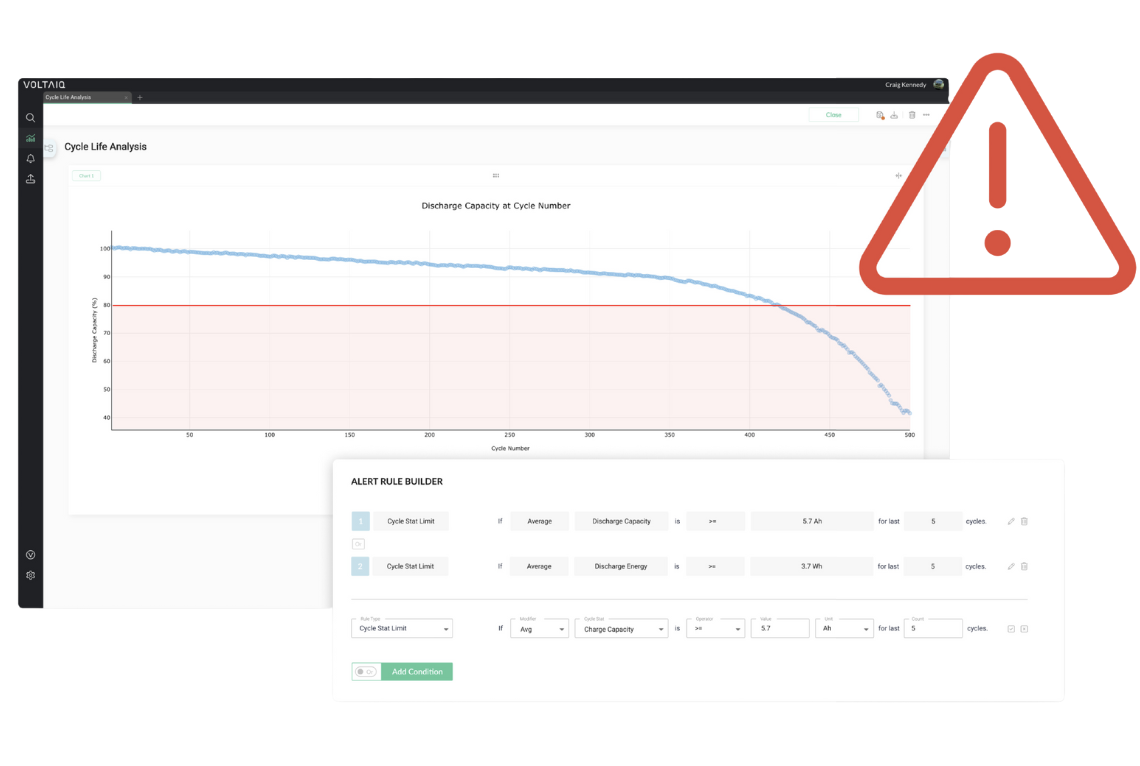

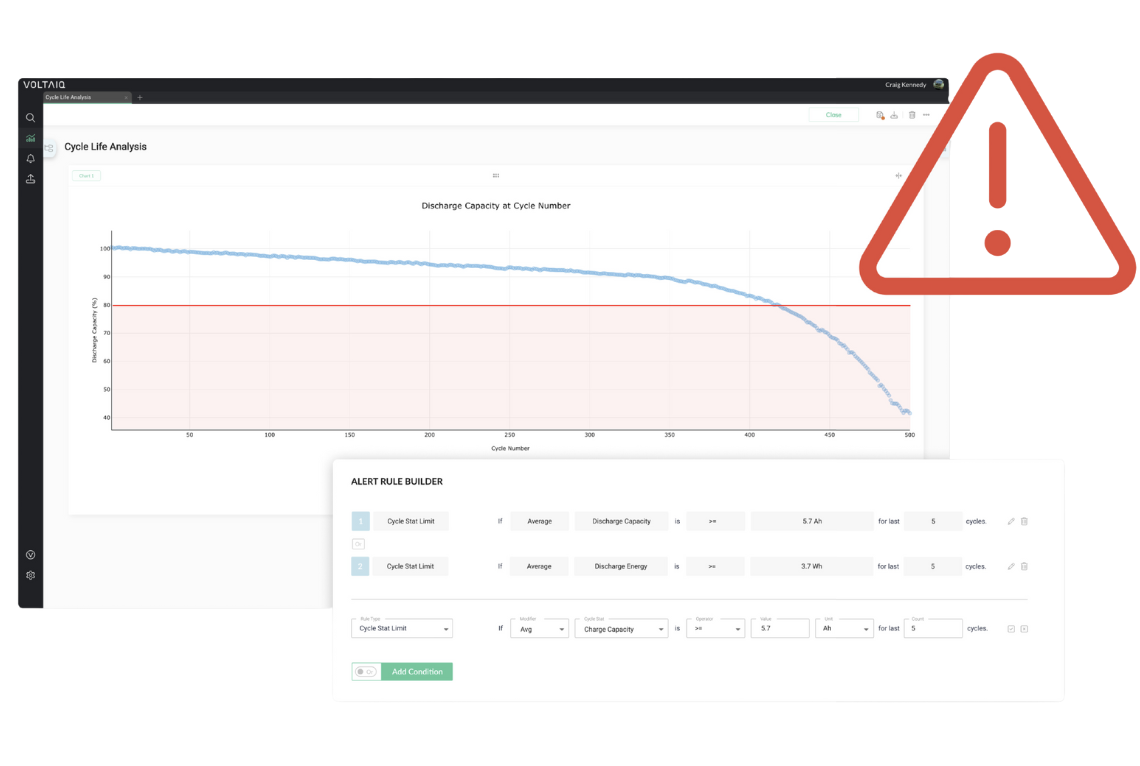

ALERTS

Catch battery issues faster.

Alerts keep you in the know, immediately notifying you of any battery anomalies.

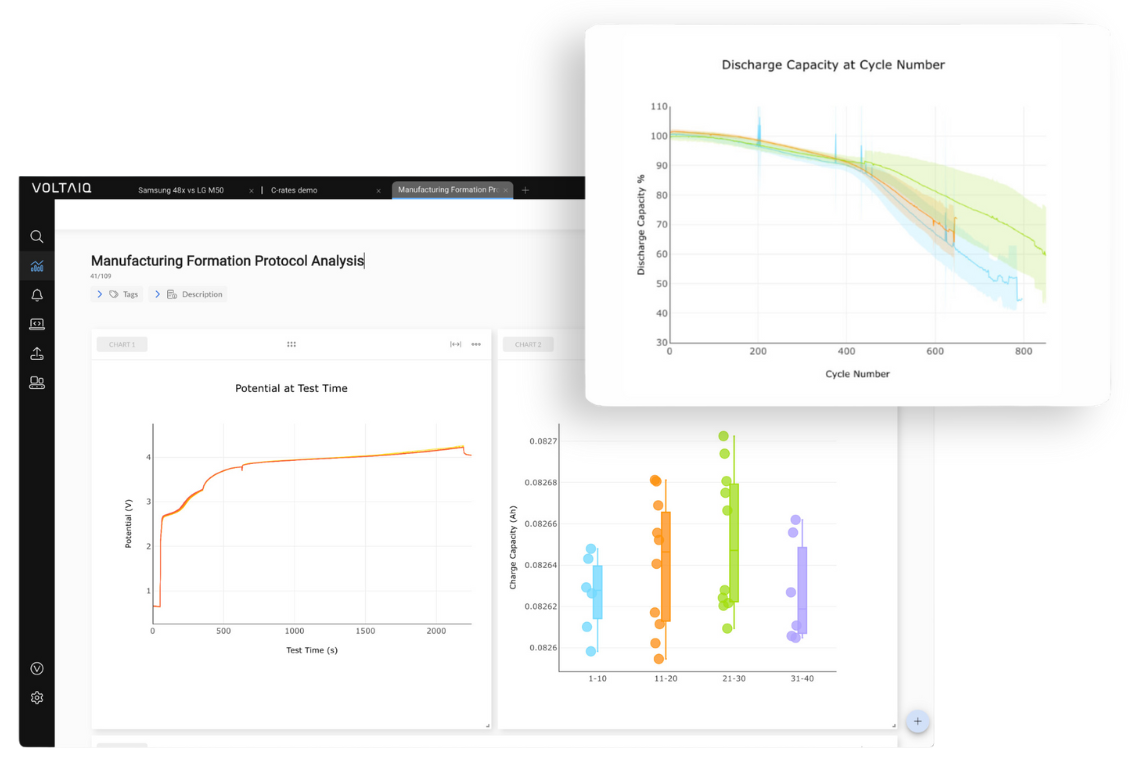

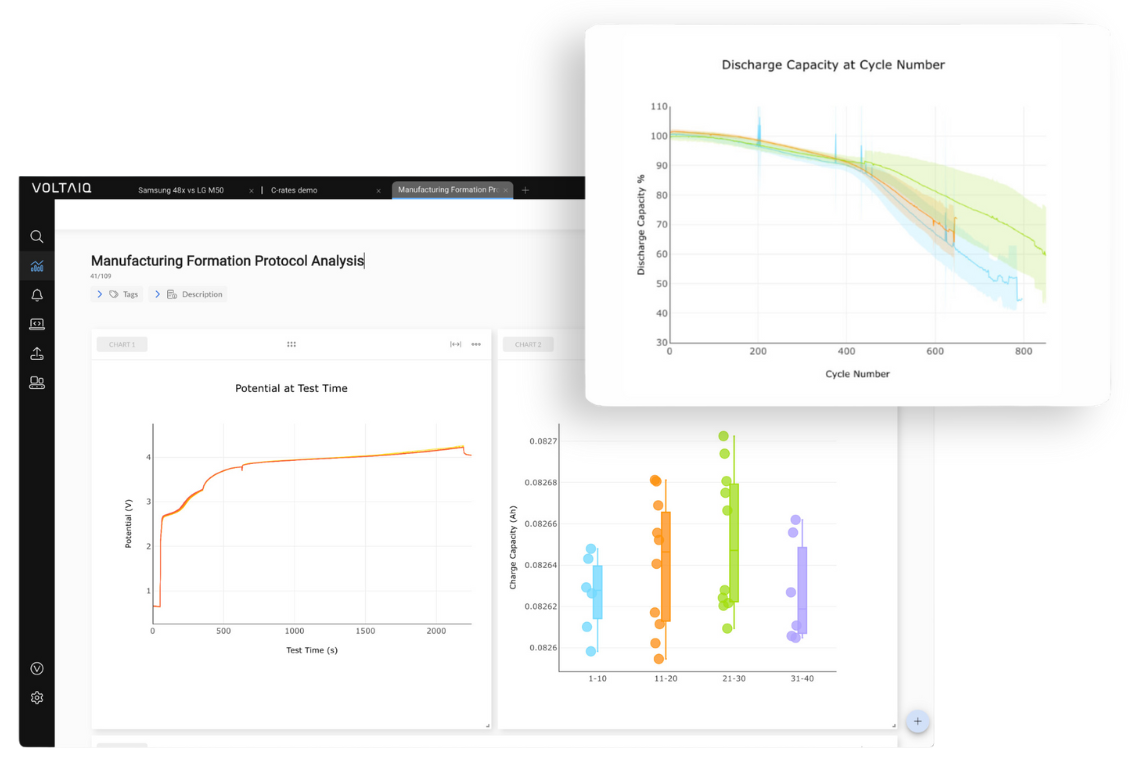

VISUALIZATIONS

Get the whole picture at once.

Whether you're testing supplier cells or manufacturing your own, get full visibility of the health of your battery program in one place.

TEST LAB DASHBOARD

View all test lab operations in one place.

Track your full test program to maximize equipment utilization and see what is being tested on what equipment, and when channels will become available.

.png)

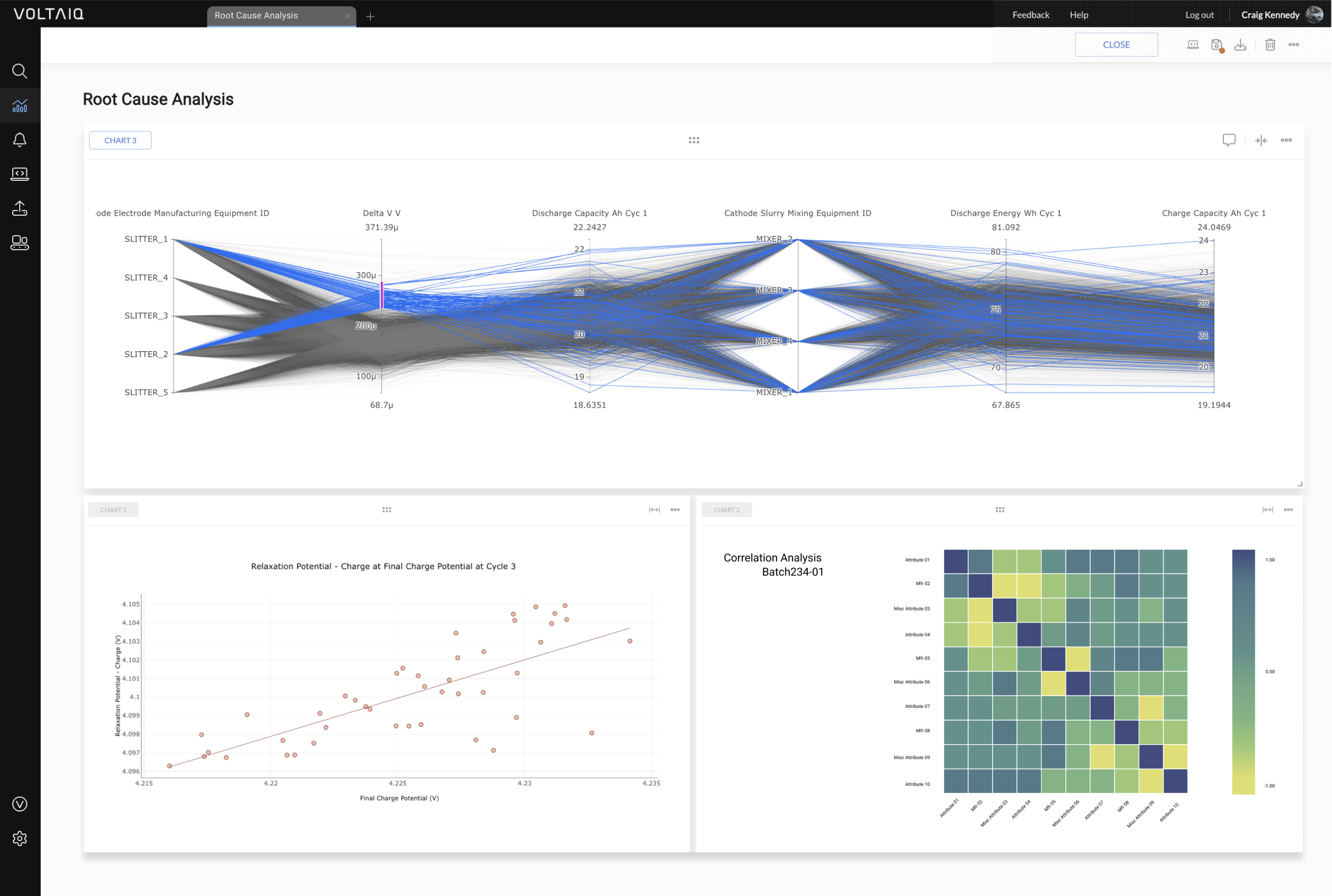

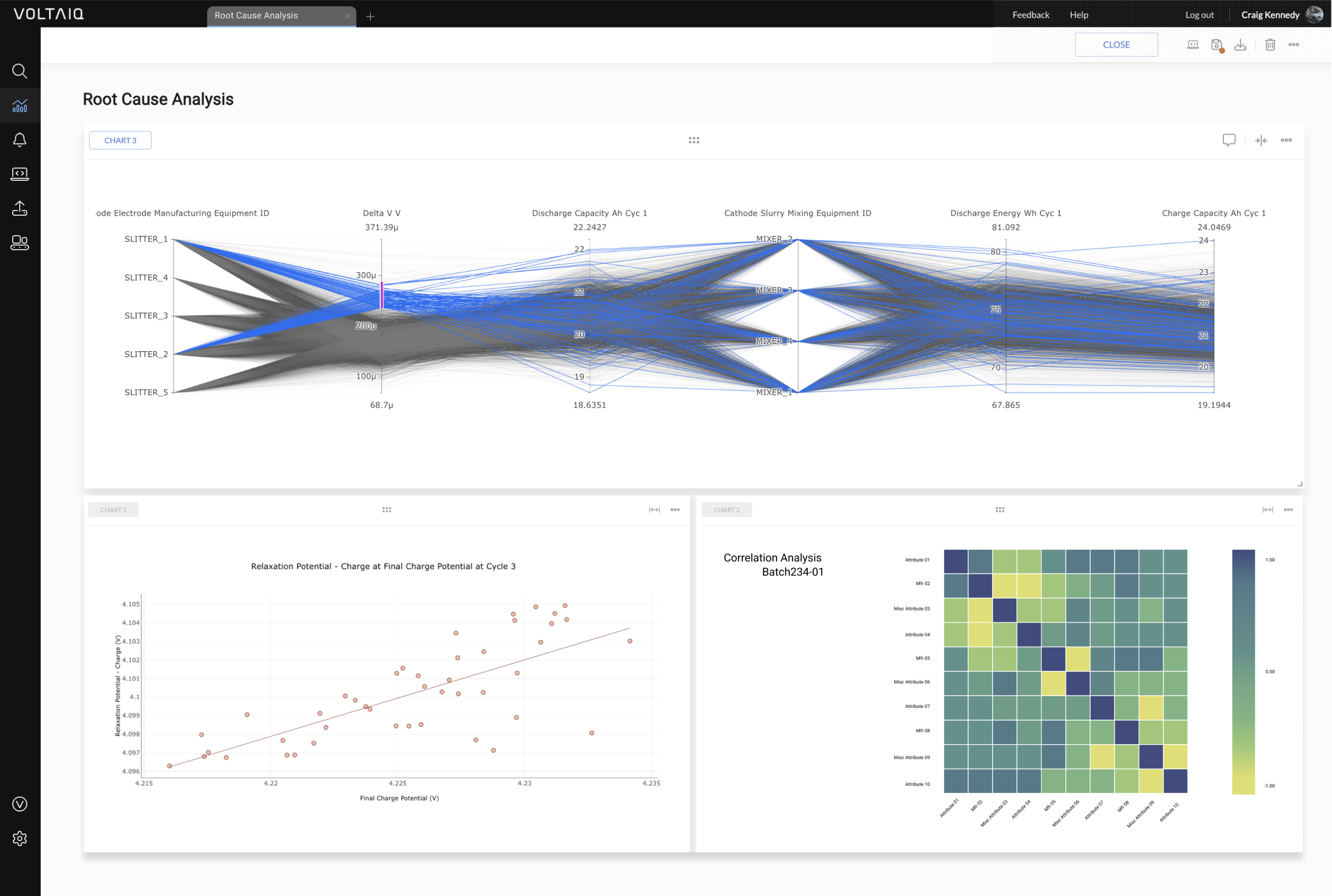

ROOT CAUSE ANALYSIS

Diagnose the cause of production issues promptly.

In a few clicks, identify which upstream processes and materials led to the defects — giving you the whole picture at once.

SHARABLE DASHBOARDS & REPORTS

Easily communicate the issue for faster resolution.

Generate reports and dashboards in just a few clicks to share your findings without having to manually gather and process data.

.png)

ALERTS

Catch battery issues faster.

Alerts keep you in the know, immediately notifying you of any battery anomalies.

VISUALIZATIONS

Get the whole picture at once.

Whether you're testing supplier cells or manufacturing your own, get full visibility of the health of your battery program in one place.

TEST LAB DASHBOARD

View all test lab operations in one place.

Track your full test program to maximize equipment utilization and see what is being tested on what equipment, and when channels will become available.

.png)

ROOT CAUSE ANALYSIS

Diagnose the cause of production issues promptly.

In a few clicks, identify which upstream processes and materials led to the defects — giving you the whole picture at once.

SHARABLE DASHBOARDS & REPORTS

Easily communicate the issue for faster resolution.

Generate reports and dashboards in just a few clicks to share your findings without having to manually gather and process data.

.png)

Ensure battery quality where it matters most.

Quality & Validation Testing

Complete your test program faster with battery quality alerts, comprehensive test visibility, greater equipment utilization, and a shorter path to insights.

Gigafactory Scale-Up

Detect quality issues and diagnose root cause weeks faster than traditional QA, accelerating production ramp cycles while reducing costly scrap waste.

Pilot Production

Dial in production tolerances and bring up your line faster with customizable battery quality metrics and full upstream process and materials traceability.

Product Development

Launch on schedule with automated quality alerts and tools to streamline battery performance analysis, modeling, and BMS algorithm development.

Battery R&D

Complete testing cycles and reach performance targets faster with automated data collection and analysis.

Module, Pack & System

Ensure incoming cell quality and integrate your functional testing with full upstream traceability to prevent faulty systems from shipping to customers.

How teams are using Voltaiq:

“Voltaiq helps us scale-up and run battery production efficiently, enabling my engineers to quickly pinpoint and resolve issues so we can keep moving forward.”

“With Voltaiq, we run a modern distributed battery program at a 70% lower cost. Most importantly my team can focus on battery engineering instead of data wrangling.”

Research & Development North America

“Voltaiq is such a game-changing solution. Eight years later and we’re still very impressed. I don’t understand why there is any barrier to adopting it. If you’re wondering if you can afford it, you can. You should be doing it. You’ll get more, better organized data with faster access. It’s a no-brainer.”

“Everybody uses Voltaiq. We’ve experienced much more rapid product development. We're able to see more of the data, more quickly, in more detail to make better decisions.”

"It’s the time savings. To do root cause analysis, FA, containment, and deployment of solutions. Also faster time for process development. What the ultimate comes down to is yield target and cost target. It all goes hand in hand."

How Voltaiq works.

The essential data infrastructure for modern battery programs.

Automated Data Collection

Collect, clean, and harmonize data from any type of battery cycling equipment.

Automated Data Collection

Collect, clean, and

harmonize battery data from your test & production equipment.

Voltaiq collects raw data from formation, end-of-line process and equipment, materials tracking systems, and test lab cyclers, harmonizing it into a common format.

Feature, KPI, and Insight Extraction

Automatically extract the metrics and insights that matter.

Feature, KPI, and Insight Extraction

Automatically extract the key metrics and insights that matter.

Voltaiq uses decades of built-in battery expertise to automatically extract advanced electrochemical quality indicators for each battery, including internal resistance, dQ/dV peaks, and many more.

Traceability

Track every material, process setting, and build condition for each battery.

Traceability

Track every material, process setting, and build condition for each battery.

Voltaiq tracks all production materials, process settings, and build conditions for each battery, linking this information to a unique digital record, including materials lots, process lines, operators on duty, and more.

No-Code Analysis

Visualize essential data in seconds, compared to days using standard methods.

No-Code Analysis

Plot essential data in seconds, compared to days using standard methods

Perform advanced analysis in a few clicks, plotting time-series data, cycle metrics, battery KPIs, and comparing batch statistics. Includes voltage vs. capacity curves, DCIR vs. cycle number, pulse analysis, dQ/dV, and much, much more.

Shareable Dashboards & Reports

Easily plot and communicate quality issues for faster resolution.

Sharable Dashboards & Reports

Easily plot and communicate battery issues for faster resolution.

Easily find and share insights, while the integrated data science environment and platform APIs enable advanced processing, analysis and integrations.

Deep battery expertise to fast-track your program.

Decades of deep battery expertise, built into the platform and embedded in Voltaiq's team, to guide you in:

-

Accelerating product development

-

Supplier qualification program design

-

Factory ramp-up and optimization

-

Advanced analytical techniques (pulse analysis, dQ/dV, etc.)

Available with your Voltaiq subscription in a consultative partnership.

How to Ensure EV & BESS quality in a world of inconsistent cell quality.

In this series we dive into the strategies and tools that system integrators can use to leverage economies of scale, while ensuring quality and minimizing warranty and safety risks.

State of the market: A new era of low cost, inconsistent quality batteries | Friday, April 4th How to qualify cells for system and pack production | Friday, May 2nd

How to negotiate supply agreements | Friday, June 11th

Ensuring quality in production | Friday, July 11th

Subscribe to the Building Better Batteries Newsletter.

Written for battery engineers and leaders in the battery industry. Find resources, trends, and insights from some of the world's top battery experts.

Power Perspectives

Hear from some of the most respected voices in batteries as Voltaiq's deep bench of industry veterans share their views on the current state and future of our sector.

The 2023 Battery Report

Battery Industry Trends: Key Insights and Trends from the Volta Foundation

Decoding the Heartbeat: Unlocking Battery Production Efficiency with Data

Better business decisions start with a better understanding of your batteries.

Ready to get started?