5 Things Battery Manufacturing Can Learn From the Semiconductor Industry

A few months ago we hosted a webinar with the focus of what battery manufacturing can learn from the behemoth that is the semiconductor industry, featuring an expert panelist with manufacturing experience in both sectors.

Here, we distill a quick review of actionable best practices for anyone in the battery manufacturing sector. To get the full experience, watch the session. Otherwise, read on.

1. Prioritize Manufacturing R&D

There’s R&D, and then there’s R&D that focuses on manufacturing.

In the 1980s, Japan gained dominance in the semiconductor market, with firms like NEC, Toshiba, and Hitachi leading in market share over US companies due to better production yields. In response, American companies like Intel shifted their focus from general R&D to manufacturing process R&D, reallocating substantial portions of their budgets to improve manufacturing efficiency and competitiveness.

This story holds some powerful lessons for the modern-day battery manufacturing industry.

We are on the cusp of an energy transformation, and the need for efficient, robust, and sustainable batteries increases every day. As our panelist underscored, this is the moment for innovation not only in the technology itself, but into how that technology is built at scale. Emulating the semiconductor industry’s model, it’s imperative for the battery sector to actively direct investments into the future of manufacturing R&D, so companies can build products more efficiently and with higher quality in the nearer term.

2. Emphasize Quality Control

We’re dealing with energy storage devices that power critical aspects of human activity – from the cars we drive to the grids that sustain our cities, and the myriad portable devices upon which modern life depends. A single malfunction could not only disrupt a consumer’s day but also tarnish a brand’s reputation, cost the manufacturer millions or even billions, or worse, endanger lives.

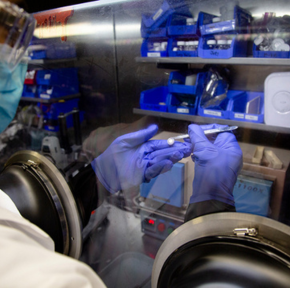

To ensure high-quality output, battery manufacturing leaders need to start by demanding better materials from their suppliers. If the starting materials are good, there’s a higher chance the final product will be too. This also puts manufacturers in a stronger position to control the final product quality because they’re not starting with poor-quality inputs. Investing in good measurement tools and software is also important to keep an eye on quality during production.

Looking back to the 1980s and the semiconductor industry once again, leading U.S. companies like Intel were pushed by Japanese competitors to invest heavily in quality control. This investment paid off with better yields and consistent products across the board. This approach, known as the “copy exact” method at Intel, meant every part of the process was the same every time, leading to reliable outcomes.

3. Collaborate with Your Supply Chain

The global supply chain network is a marvel of modern logistics, perfected by the semiconductor industry despite its susceptibility to geopolitical and market pressures. Battery manufacturing leaders should take note of this resilience, especially when their raw materials come from politically and environmentally sensitive areas, prone to causing supply chain upheavals.

One key strategy to adopt is “ship to control,” a principle that mandates suppliers cannot ship their materials until they provide concrete quality testing data for each specific batch. This is about receiving not just a promise that materials meet the specifications, but the actual data to prove it.

Furthermore, supply chain resilience requires implementing “fingerprinting” and stringent change control processes. These measures mean that any alteration in a supplier’s process, or even in their own suppliers’ processes, must be communicated in advance. It allows for a re-qualification of materials and, if necessary, recalibration of equipment to ensure continuity in quality. Essentially, it ensures that manufacturers are not blindsided by upstream changes that could compromise the final product.

4. Prioritize Data-Driven End-of-Line Testing

In the semiconductor industry, end-of-line testing greatly improved when companies started to emphasize the importance of data in quality assurance.

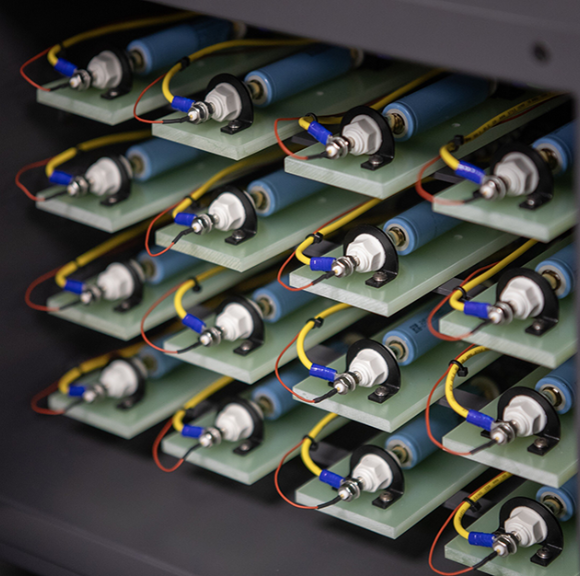

Similarly, in battery manufacturing, capturing and analyzing detailed electrochemical data from each cell during formation cycling can provide a wealth of insights into the health and longevity of the product. By thoroughly analyzing formation cycling data—much like a cardiologist interprets an EKG to detect a heart murmur—manufacturers can uncover intricate battery health indicators that go far beyond simply confirming if the cell reached its expected voltage.

This deeper analysis of formation cycling data enables the extraction of advanced health and quality metrics, providing a comprehensive view of each battery’s long-term performance and reliability. This data-driven approach enables manufacturers to predict performance and identify potential issues before they become costly problems.

5. Integrate Comprehensive Data Systems

The semiconductor industry long ago learned to rely on data for quality control, and battery manufacturing leaders need to do the same.

By using IT systems that track all parts of the supply chain and manufacturing, they can spot and solve problems much faster. This means getting data from suppliers on the materials they send, keeping a close eye on the battery assembly process, and looking at how each battery performs in the final testing stages.

When manufacturers can see and analyze all this information, they can understand what’s working and what isn’t, sometimes reducing problem-solving time from weeks to days. With a good system, they can also make better use of formation cycling data from the end of production, where each battery is both “finalized” electrochemically and evaluated by charging and discharging. This isn’t just about checking if the battery works; it’s about making sure it’s going to last and be safe. In the end, being able to trust the batteries you sell starts with understanding every step that went into making them.

Seizing the Future

Insights from the webinar offer proven strategies from the semiconductor industry for battery manufacturing. As the battery sector stands on the brink of its own era of growth, these lessons are more important than ever.

Want to explore more about these insightful parallels and the future they could help forge for the battery industry? We invite you to watch the full webinar for a deeper dive into this fascinating topic. Join us in learning from the past and innovating for the future!

Related Posts

The 2023 Battery Report

Battery Industry Trends: Key Insights and Trends from the Volta Foundation

Decoding the Heartbeat: Unlocking Battery Production Efficiency with Data

Subscribe to the Building Better Batteries Newsletter.

Written for battery engineers and leaders in the battery industry. Find resources, trends, and insights from some of the world's top battery experts.