Blog

The 2023 Battery Report

I had the pleasure to sit down with Yen T. Yeh, Executive Director at the Volta Foundation to dive...

Battery Industry Trends: Key Insights and Trends from the Volta Foundation

I sat down recently with Yen T. Yeh, Executive Director at the Volta Foundation to dive into their...

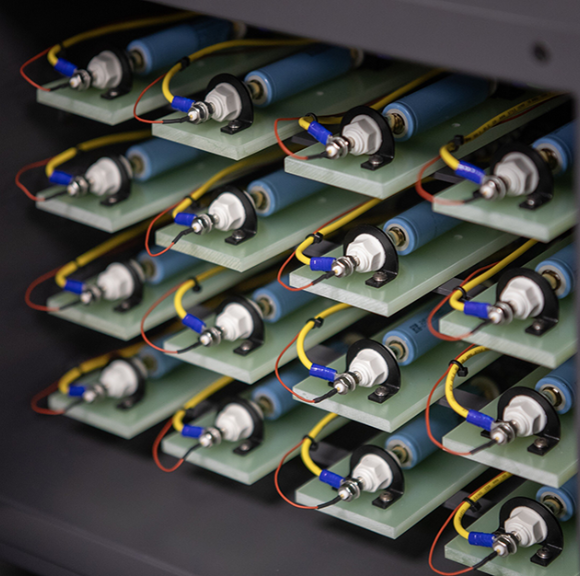

Decoding the Heartbeat: Unlocking Battery Production Efficiency with Data

How a battery’s charge-discharge cycle data can transform battery production.

Battery Market Trends from China and Beyond: Strategic Insights for Global Industry Challenges

The Chinese battery market is expected to grow at a compound annual growth rate (CAGR) of more than...

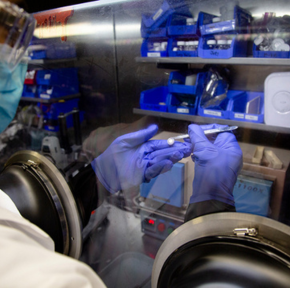

Scaling Lithium-Sulfur Batteries: From Pilot to Gigafactory

In a recent webinar, we brought together a panel of industry leaders to discuss the evolution of...

Lessons Learned Working at the Gigafactory

In a recent webinar, we gathered together a panel of gigafactory veterans to explore the lessons...

Navigating the Complexities of the Battery Manufacturing Process: Expert Insights and Strategies

In an era increasingly focused on sustainable energy solutions, understanding the complexities of...

Siemens and Voltaiq Collaborate to Optimize Battery Manufacturing

The world is relying on battery-powered products more than ever, from the largest vehicles to the...

5 Things Battery Manufacturing Can Learn From the Semiconductor Industry

A few months ago we hosted a webinar with the focus of what battery manufacturing can learn from...

Understanding Batteries: A Comprehensive Overview

The future is battery-powered. From running smartphones and electric vehicles to providing the...

5 Reasons Building a Gigafactory is Harder than Everyone Thinks

As we’ve said before, building a battery factory is hard. Building a gigafactory is akin to...

Reducing Battery Scrap Rates: The Power of Enterprise Battery Intelligence

As the demand for high-capacity, high-performance batteries continues to grow, the battery...

Subscribe to the Building Better Batteries Newsletter

Written for battery engineers and leaders in the battery industry. Find resources, trends, and insights from some of the world's top battery experts.