Why Every Company Needs Industry-Leading Battery Technology

Some technological trends are so big that they impact every industry and every company.

Shortly after the turn of the millennium, every company on earth realized that they had to figure out how they were going to leverage the internet to survive and thrive. It didn’t matter whether they were obviously “an internet company.” They needed a strategy, or else they’d get left behind.

Today, the same is true for electrification – a term that refers to a broad set of transformations driven by battery technology. As fossil fuels are phased out, and everything in modern life becomes reliant on electric power, most companies will live or die on their battery strategy.

Properly investing in battery technology solutions means better product launches, higher customer satisfaction, and a faster return on investment. Failing to invest means fires, lawsuits, and brand damage. Leaders need to understand the complexity and subtlety of batteries, so that they can pursue the right strategy.

The Electrification Wave Has Arrived

Batteries have been around since 1800, when they were first invented by Alessandro Volta. Since then, they have been steadily improving. By the latter half of the 20th century, they offered inexpensive, ubiquitous, and storable power solutions.

However, advances in lithium-ion batteries over the last two decades have triggered a paradigm shift. The global battery market, which was projected to be worth US$120.4 billion in 2020, is expected to grow to US$279.7 billion by 2027, at a CAGR of 12.8%. This class of batteries are changing the world.

4.88 billion people, or 62% of the global population, are carrying around battery-powered phones every day. But the real transformation relates to how batteries have changed every element of our lives. Batteries are at the heart of everything: how we connect and communicate, find information, transport people and goods, and power our homes and buildings. The category leaders in these spaces will be the next generation of dominant ventures.

Take electric vehicles. Tesla’s stock is worth more than every other car company. Electric vehicle maker Rivian has yet to deliver a single customer vehicle – but is seeking an $80 billion valuation in its IPO.

These EV signals show where the wind is blowing. The electrification wave is just starting to break. It is impossible to overstate the importance of batteries in modern society; they will be core to every technology category, whether enterprise or consumer. As the age of fossil fuels gradually winds down, in the coming years, the companies that win will be the companies with a better battery strategy than their competitors.

Elements of a Winning Battery Strategy

If properly designed, batteries can provide a huge competitive edge – and trillions of dollars in value. Combined, Tesla and Apple have a market capitalization of over $3T, on the basis of battery-powered product offerings and all-round battery excellence. For Apple, the introduction of the iPod marked a transition toward a battery-powered product range (and business model). Tesla released their first Roadster in 2008, and have been dominant battery players ever since.

However, there is a flipside. Battery-powered products such as these are powerful value-creators if companies get them right. But if they get them wrong, they can face multibillion-dollar recalls and serious brand damage.

Getting your battery strategy right means understanding a few key principles, and grasping the complexities that are inherent to battery technology.

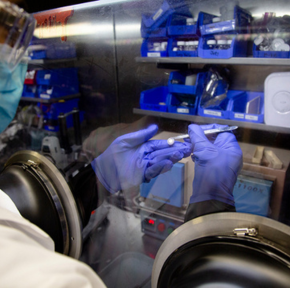

Acquire the Data You Need

What is inside a battery? The answer: lots. Batteries, unlike other inanimate mechanical or electrical components, are like living organisms. Inside of them, a plethora of chemical and physical processes are constantly in motion. Every charge-discharge cycle, billions of tiny particles (lithium ions) must diffuse from the cathode of a battery to the anode and back again, almost as if the battery is breathing.

Batteries have inherent performance variability; they can degrade gradually or abruptly. As with most living things, there is no simple equation or model that can tell you how healthy a battery is, or how long it will last. If your engineering team does not treat batteries as organisms, errors caused by this lapse in judgment can be detrimental to the entire product lifecycle.

How do you understand a battery? The same way you understand any complex organism. You collect data. You need data on how your battery technology was manufactured and operated, and how it performed. More precisely, you need lots of data – all the data you can get your hands on. And then you need to perform a lot of analysis – the most sophisticated, comprehensive analysis possible. Only with this in-depth approach can you truly understand your batteries, and effectively optimize your battery strategy.

Avoid Battery Blow Ups

In the list of make-or-break success factors, this might be top of the list. In short, batteries have a tendency to explode. This presents serious safety concerns.

Lithium-ion batteries contain flammable materials, and it is a fundamental law of the universe that when you pack a lot of energy into a small space, the risk of an explosive event increases. High-profile battery fires in automobiles, as well as grid energy storage deployments, continue to make headlines.

Samsung suffered billions of dollars in losses when the Galaxy Note caught fire in people’s pockets. And smartphones are far from the only product that is prone to substandard batteries. The US National Highway Traffic Safety Administration issued a recall for 2019–2020 Hyundai Kona and 2020 Hyundai Ioniq electric vehicles after more than a dozen battery fires were reported. Hyundai announced it would recall 82,000 vehicles at a cost of $900 million.

Likewise, Ford recalled around 20,500 Kuga plug-in hybrid crossovers in 2020 due to worries that the battery packs in the vehicles could potentially overheat and cause a vehicle fire. Damages totaled more than $400 million for the corporation.

High-profile battery-powered device recalls like this can cost billions of dollars in damages. On top of this, there is the serious reputational damage that can follow. With so much at stake, it is critical that batteries and battery systems are properly and safely designed from the start.

Product timelines are always tight, and battery engineering talent is scarce. But companies cannot afford to cut corners with the safety of their battery technology. They need to ensure they get the data and insights they need to execute with peace of mind.

Be Alert to a Changing Battery Landscape

Possibly more than any other technology category, battery technology is constantly evolving. While lithium-ion batteries have established market dominance in the last few years, there is still enormous variation across form factors, chemical formulations, internal components, and other characteristics. This complexity is compounded as OEMs innovate and improve their offerings, new players enter the market, and research advancements break through to the commercial market.

A couple of present-day examples of this consistent innovation include the phasing out of cobalt from battery formulations due to both economic and ethical concerns, and the gradual incorporation of silicon into lithium-ion battery anodes in pursuit of better performance.

As more businesses discover that their success is linked in some way to the latest battery technology, it can be a challenge to stay on top of these trends and determine which battery to bet on for your business.

By 2030, China’s demand for lithium-ion batteries for electric vehicles is expected to reach 740 GWh; half of global demand. This demand will be mimicked in every other electrified vertical. Several European countries have also committed to phase out combustion engines during this time period. How can leaders meet this demand? By embracing the newest tools that will maximize the value of batteries and avoid costly mistakes.

Adapt to Labor Shortages Through Software Solutions

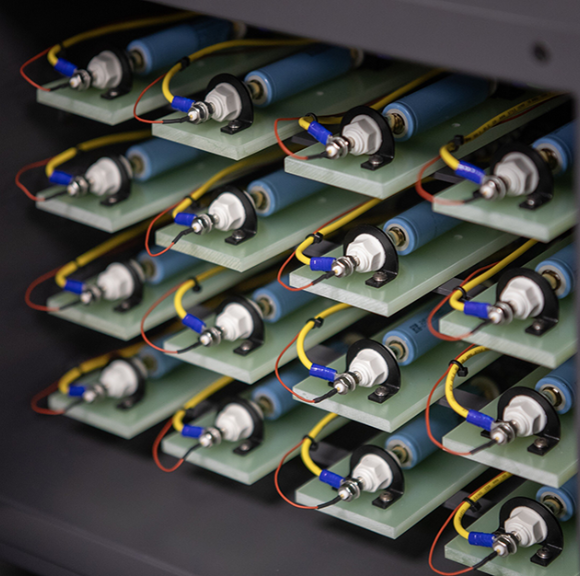

As batteries become more widely used in grid storage, automotive, and heavy industrial applications, a new engineering discipline has emerged. This discipline is centered on combining large numbers of relatively small battery cells into monolithic, large-scale battery technology systems.

This is every bit as complex as it sounds. Combining these small battery cells into larger systems is every bit as difficult as designing a new internal combustion engine. And right at the moment when these development pressures are so high, industry is experiencing a scarcity of human capital and modern tools.

By 2030, the global talent shortage is expected to reach 85.2 million workers. Companies around the world risk losing $8.4 trillion in revenue due to a shortage of skilled workers. Battery engineers make up a minority of the shortfall – but they are a crucial component. Companies need to think about how they can optimize their battery strategy and remain competitive despite potential hiring difficulties.

SaaS solutions are proving crucial here. Companies should make sure they leverage tools that can replace any gap in human capital. As the electrification of every industry gathers pace, many companies and providers are creating software tools to help companies analyze and optimize their battery technology.

The Role of Enterprise Battery Intelligence

The battery revolution is upon us. Savvy leaders should be looking to get ahead of their competition, and refine every element of their battery strategy. Here at Voltaiq, we are empowering businesses to achieve this goal through the application of Enterprise Battery Intelligence (EBI).

Our platform helps our users design, develop, manufacture, operate, and finance the next generation of battery-powered products. How? By simplifying the mountains of battery data generated by various sources. Enterprise Battery Intelligence is critical in safely achieving electrification goals, while maximizing the ROI on battery investments.

Our platform empowers our users to handle all of the data, so that engineering teams can focus on what matters most: improving products. We work with leaders in consumer electronics and transportation OEMs, as well as materials and cell suppliers, to drive battery excellence across the full product lifecycle.

Related Posts

The 2023 Battery Report

Battery Industry Trends: Key Insights and Trends from the Volta Foundation

Decoding the Heartbeat: Unlocking Battery Production Efficiency with Data

Subscribe to the Building Better Batteries Newsletter.

Written for battery engineers and leaders in the battery industry. Find resources, trends, and insights from some of the world's top battery experts.