5 Reasons Building a Gigafactory is Harder than Everyone Thinks

As we’ve said before, building a battery factory is hard. Building a gigafactory is akin to assembling a thousand-piece puzzle where every piece is susceptible to the slightest environmental change. This complexity emerges from the depths of battery chemistry, the speed of industry innovation, and the deluge of data that these factories generate. Toss in the challenge of integrating diverse systems and implementing cutting-edge data science at a massive scale, and you’ve got a recipe for one of the most intricate industrial processes of our time.

Here, we break down five key factors that people often overlook or underestimate. And we break down how Enterprise Battery Intelligence (EBI) can make the daunting task of building a gigafactory (and then successfully operating it!) more streamlined.

-

The vast complexity of battery manufacturing

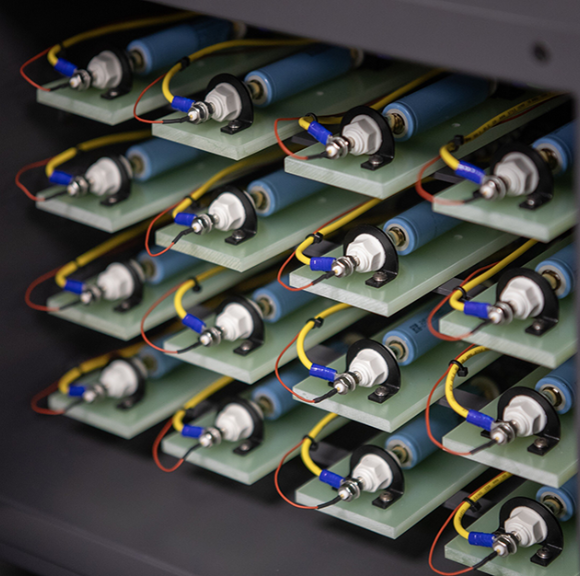

The battery manufacturing process is governed by many thousands of highly sensitive variables.

A slight variation in temperature or humidity, and minor changes in the composition or quality of raw materials, can significantly affect the performance, safety, and lifespan of the finished product. Battery chemistries vary, each having its unique requirements for optimal manufacturing conditions. Materials properties, slurry viscosities, equipment setpoints, densities, temperatures, pressures, speeds, and the final “formation cycling” procedures — all of these need to be finely controlled.

If any of the variables aren’t kept within tolerance, it’s impossible to produce quality batteries with low scrap rates.

And when these complexities are scaled to the level of building a gigafactory, the variable space is effectively unmanageable unless you have the right tools, controls, and data analysis capabilities. Extensive investment in precise control systems and constant monitoring is required, as are stringent quality checks to ensure the consistency and reliability of the end product. Moreover, integrated data acquisition and analysis are required. All of this is a mammoth task given the size and production volumes of gigafactories.

-

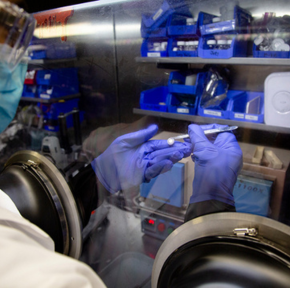

Ever-evolving battery technology

The battery industry is marked by constant innovation. There is a continuous change in battery technology, with the advent of new chemistries, larger form factors, and new manufacturing techniques. There are constant shifts in the industry, such as new supply chain developments or the introduction of novel technologies. This means that gigafactories must be built with flexibility and adaptability in mind. Of course, mass manufacturing doesn’t naturally lend itself to flexibility; ideally, any full-scale production line would simply deliver the product without ever needing any changes. Thus, the need for agility and adaptability makes the task of building and running a gigafactory all the more challenging. To keep pace with these changes, factories must continually invest in new technologies, training, and systems, adding to the complexity and cost.

-

Overwhelming quantities of manufacturing data

The vast amounts of data generated during various stages of battery production need to be effectively harnessed to improve manufacturing processes. From aligning disparate data sources to cleaning the accumulated data and extracting useful features, the data management burdens in building a gigafactory are significant. Moreover, to convert this data into actionable insights, sophisticated and domain-specific data analytics tools and skills are necessary.

Being able to predict potential issues, improve production efficiencies, and control quality using data analytics can be a game-changer for these factories. However, setting up these systems and cultivating the required expertise is no small feat. (This is why the industry often resorts to “eyeball” estimates and gut feelings for optimizing battery production processes, with much of the data analysis performed manually.)

-

Systems integration challenges

The internal IT/OT architecture of a gigafactory is incredibly complex. Going “from shop floor to top floor,” you will find an array of sensors; programmable logic controllers (PLCs); a SCADA (supervisory control and data acquisition) layer; manufacturing execution systems (MES), enterprise resource planning software (ERP) — and more.

While this panoply of systems represents a significant integration challenge, these are ultimately the data sources whose synthesis will enable a factory to ramp up quickly and operate effectively in a steady state. As such, smart factories require data collection, storage, and processing via cloud or edge solutions. Production process control, monitoring, and reporting need to be put in place for all plant KPIs, including overall equipment effectiveness (OEE), scrap rate, energy consumption, and so on.

Establishing this robust, scalable, and future-proof IT architecture is like piecing together a massive jigsaw puzzle. Effective integration requires a deep understanding of different software platforms, and often customized solutions to ensure a cohesive result. In addition to this, as the gigafactory evolves and changes, these interfaces must be continually updated and maintained, adding to the challenge. And failure means that data exchange will be suboptimal, causing disruptions or errors — possibly major ones.

-

ML, AI, and data science at scale are hard

While machine learning (ML), artificial intelligence (AI), and data science are potential game-changers for battery manufacturing, their implementation at the scale of a gigafactory is challenging, to say the least. Developing and fine-tuning ML/AI models that can deal with the sheer volume of data generated in these factories requires considerable computational resources and expertise. Further, creating models that can adapt to continually changing production parameters and still deliver reliable predictions is an ongoing challenge. The need to translate these insights into real-time actions adds another layer of complexity — especially when a talent vacuum in the battery production industry means there aren’t enough experienced engineers to fill all the factories planned to be built.

How can Enterprise Battery Intelligence (EBI) help?

Enterprise Battery Intelligence has the potential to greatly simplify the challenges associated with building a gigafactory — and its operation.

By integrating with existing systems and harmonizing disparate data sources, EBI can provide a coherent view of the entire production process, from raw materials to finished product. This unified view facilitates better decision-making, helping to manage the technical complexities of battery production at such a large scale. EBI enables the seamless interplay between different systems and tools already used by businesses, thereby reducing potential disruptions and errors.

The advanced data analytics built into a platform like Voltaiq can effectively transform vast amounts of data into actionable insights, empowering factories to quickly ramp yield and throughput, anticipate potential issues, enhance production efficiencies, and maintain high-quality standards.

Moreover, EBI tools come equipped with machine learning capabilities that are scalable, offering the much-needed capacity to handle gigafactory-level data. By developing library templates of different machine learning algorithms, they offer a solid foundation for the deployment of advanced data science projects. To state it plainly, EBI capability is a prerequisite for deploying ML and AI at scale and in production for battery manufacturing.

With the use of modern analytical workflows, a solution like Voltaiq enables collaboration and sharing of scripts and analyses among teams, which is pivotal in a large-scale setup like a gigafactory. EBI can also help factories stay agile and adaptable, by providing a platform that can quickly respond to changes in the industry, making it an indispensable tool for the burgeoning battery industry.

Related Posts

Subscribe to the Building Better Batteries Newsletter.

Written for battery engineers and leaders in the battery industry. Find resources, trends, and insights from some of the world's top battery experts.