Conamix accelerates with force-multiplier analytics from Voltaiq

Conamix, developing next-generation battery technology, replaced custom analysis scripts with Voltaiq to eliminate data bottlenecks, improve team onboarding, and rapidly adapt to new product applications.

The problem

As Conamix's battery development program scaled, their team faced mounting pressure: rapidly growing volumes of test data, limited engineering resources, and the constant challenge of making faster decisions without sacrificing analytical depth.

"The key challenges were how fast we were able to process data and at what level of detail," explains Stephen Burkhardt, Chief Technology Officer at Conamix. "There's always this speed versus quality of analysis question."

The workflow was labor-intensive. Engineers manually exported data from cyclers, consolidated results in Excel, and created individual plots—working with one file at a time. The volume of data that needed analysis far outpaced the team's capacity to process it efficiently.

Beyond speed, the data access created organizational friction. New team members faced steep learning curves before they could work effectively with battery test results. As technical demands increased, these barriers compounded.

"Anytime there's a barrier to doing something, there are going to be other priorities," Stephen notes. The team needed a solution that would amplify their capabilities rather than consume their time.

The solution

Conamix chose the Voltaiq Enterprise Battery Intelligence platform for:

- Deeper analysis at scale for faster decision making

- Streamlined onboarding and democratized data access

- Access to a continuously improving solution

Faster decisions, democratized access

Voltaiq fundamentally changed the speed-versus-quality trade-off that had constrained Conamix's development pace.

"Voltaiq puts us on a completely different curve," says Stephen. "We're able to see more of the data more quickly, in more detail, and make better decisions about next experiments."

What previously required hours of manual data wrangling now happens in seconds. Engineers build essential visualizations immediately, analyze multiple datasets simultaneously, and spend their time interpreting results rather than processing files—a force multiplier that allows a lean team to accomplish far more.

The barrier to entry for new team members disappeared entirely. "New people coming in, we get them set up immediately with a Voltaiq ID," explains Stephen. "They're able to log in to the standard view that we have and see all of the data very quickly with a very low bar from the perspective of having to learn new analysis tools."

This democratized access accelerates development across Conamix's organization. Teams focused on lithium metal anode development, cycle life optimization, cathode engineering, and analytical characterization all use Voltaiq for their electrochemical data analysis. "People develop within their roles much more quickly," Stephen notes, "and oftentimes develop beyond their roles much more quickly."

Build vs. Buy: Choosing a sustainable solution

Stephen understood that sustainable data infrastructure requires institutional continuity and ongoing evolution—critical when every engineering hour must count.

"People come and go," Stephen explains. "We needed to know there would be continuity in whatever analysis solution we were using." Internal systems create dependency on individuals who understand their architecture. When those people leave, institutional knowledge walks out the door.

Beyond continuity, building and maintaining internal tools carries an ongoing resource cost. "The in-house solution also doesn't guarantee new tools or features," Stephen points out. "Voltaiq is a better solution from that perspective of continuous improvement."

Stephen describes Voltaiq as a "force multiplier"—tools that enable a focused team to deliver sophisticated analysis without requiring a large specialized group. "The analysis tools we have access to in Voltaiq are those force multipliers," he explains. Rather than dedicating scarce engineering time to maintaining infrastructure, Conamix benefits from continuous platform evolution while staying focused on advancing battery technology.

Impact

Voltaiq's force multiplier effect enabled rapid adaptation to new opportunities with Conamix's existing team.

When Conamix began exploring a new product application, Voltaiq's historical data access proved critical. "Because we have the data digitized and we're able to filter it and easily go back through old experiments," Stephen explains, "we've been able to look at past electrolyte formulations, find formulations that weren't moving the needle in a significant way on the automotive cell but do demonstrate improved energy and power performance, and we've been able to apply those quickly to the new application."

Engineers spend their time interpreting data and designing experiments rather than wrangling files. New hires contribute immediately. A focused team delivers outsized results.

"We've experienced much more rapid product development," Stephen reflects.

About Conamix

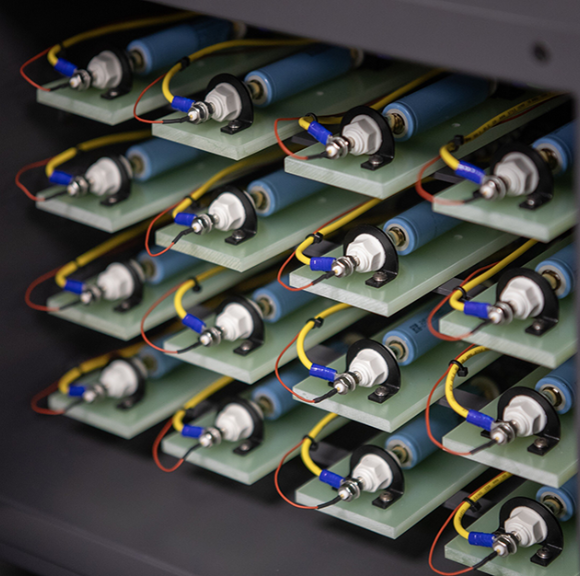

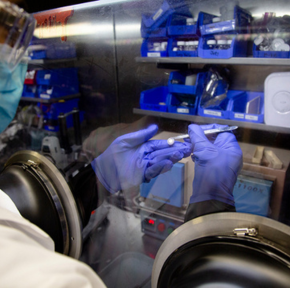

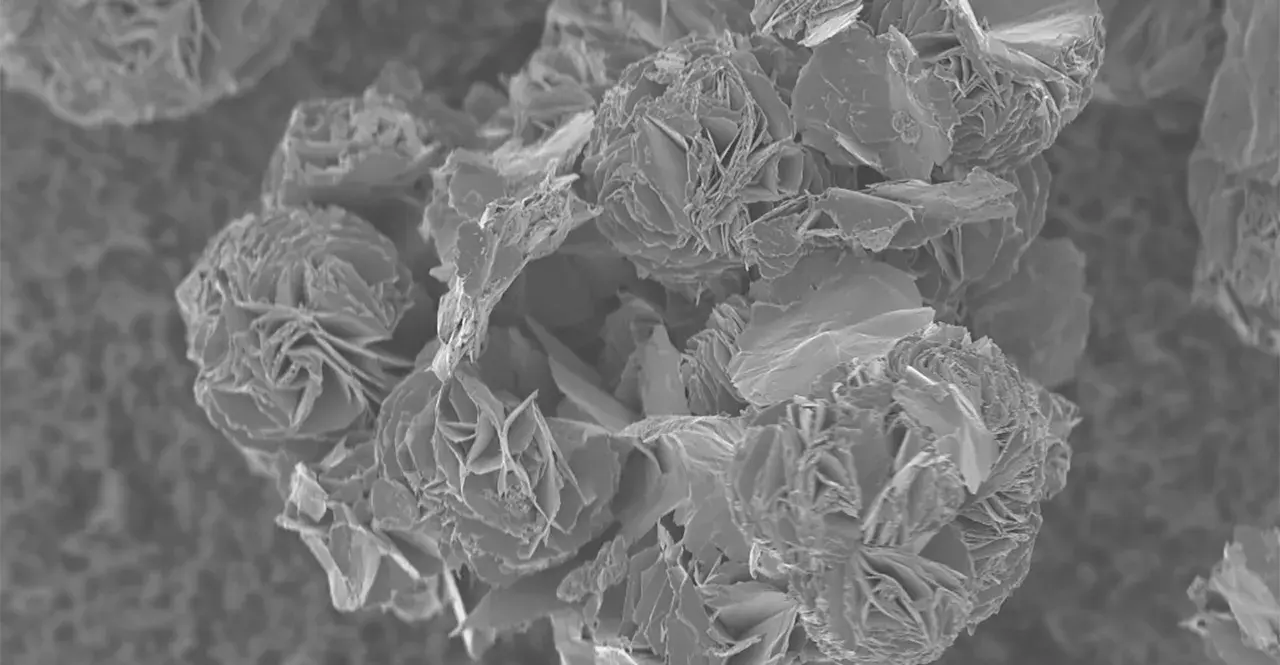

Conamix specializes in Lithium-Sulfur battery technology that lowers costs and enhances performance across a wide range of applications without relying on expensive materials or constrained supply chains. Their portfolio of proprietary technology enables Conamix to address multiple markets including drones, micromobility, and EV applications.

Conamix addresses every challenge that hinders lithium-sulfur (Li-S) performance with technology built on a thorough understanding of everything from fundamental materials chemistry to the design and manufacturing of battery cells and packs.

"We needed to know there would be continuity in whatever analysis solution we were using. Voltaiq puts us on a completely different curve."

Better business decisions start with a better understanding of your batteries.

Ready to get started?

-1.png)